Threadmill Internal Through Coolant (Reg) – ISO

Product Code: ISO METRIC

Categories: SOLID CARBIDE TOOLS, Thread Mill

Icon Guide:

- Technical Specification

- Tool Selection Chart

- Tool Parameters

- Product Drawing (PDF)

ISO METRIC

|

ITEM CODE

|

Thread

|

|

Pitch

|

Dimensions (mm)

|

|

|

|

|

No. of Flutes

|

Drill Dia

|

|

Internal

|

M Coarse

|

M Fine

|

mm

|

d

|

D

|

l2

|

0

|

L

|

Z

|

mm

|

|

TMI/E. 03.050.3HI. 040024. R-ISO

|

M3X0.5

|

M3.5-M16x0.5

|

0.5

|

4

|

2.4

|

6.0

|

6.2

|

45

|

3

|

2.5

|

|

TMI/E. 04.050.3HI. 040032. R-ISO

|

|

M4x0.5

|

0.5

|

4

|

3.2

|

8.0

|

8.2

|

45

|

3

|

3.5

|

|

TMI/E. 05.050.3HI. 060042. R-ISO

|

|

M5x0.5

|

0.5

|

6

|

4.2

|

10.0

|

10.2

|

57

|

3

|

4.5

|

|

TMI/E. 04.070.3HI. 040031. R-ISO

|

M4x0.7

|

|

0.7

|

4

|

3.15

|

8.4

|

8.7

|

45

|

3

|

3.3

|

|

TMI/E. 06.075.3HI. 060050. R-ISO

|

|

M6x0.75

|

0.75

|

6

|

5.0

|

12.0

|

12.4

|

57

|

3

|

5.3

|

|

TMI/E. 05.080.3HI. 040039. R-ISO

|

M5x0.8

|

|

0.8

|

4

|

3.9

|

10.4

|

10.8

|

45

|

3

|

4.2

|

|

TMI/E. 06.100.3HI. 060048. R-ISO

|

M61.0

|

M8-M40x1.0

|

1.0

|

6

|

4.8

|

12.0

|

12.5

|

57

|

3

|

5.0

|

|

TMI/E. 08.100.3HI. 080067. R-ISO

|

|

M8x1.0

|

1.0

|

8

|

6.7

|

16.0

|

16.5

|

61

|

3

|

7.0

|

|

TMI/E. 10.100.3HI. 100087. R-ISO

|

|

M10x1.0

|

1.0

|

10

|

8.7

|

20.0

|

20.5

|

73

|

3

|

9.0

|

|

TMI/E. 12.100.4HI. 120107. R-ISO

|

|

M12x1.0

|

1.0

|

12

|

10.7

|

24.0

|

24.5

|

73

|

4

|

11.0

|

|

TMI/E. 08.125.3HI. 080065. R-ISO

|

M8x1.25

|

|

1.25

|

8

|

6.5

|

16.2

|

16.9

|

61

|

3

|

6.8

|

|

TMI/E. 10.125.3HI. 100085. R-ISO

|

|

M10x1.25

|

1.25

|

10

|

8.5

|

20.0

|

20.6

|

73

|

3

|

8.8

|

|

TMI/E. 10.150.3HI. 100082. R-ISO

|

M12-M48x1.5

|

1.5

|

10

|

8.2

|

19.5

|

20.2

|

73

|

3

|

8.5

|

|

|

TMI/E. 12.150.4HI. 100099. R-ISO

|

|

M12x1.5

|

1.5

|

10

|

9.9

|

24.0

|

24.7

|

73

|

4

|

10.5

|

|

TMI/E. 14.150.4HI. 120119. R-ISO

|

|

M14x1.5

|

1.5

|

12

|

11.9

|

28.5

|

29.2

|

80

|

4

|

12.5

|

|

TMI/E. 16.150.4HI. 140139. R-ISO

|

|

M16x1.5

|

1.5

|

14

|

13.9

|

31.5

|

32.2

|

92

|

4

|

14.5

|

|

TMI/E. 12.175.4HI. 100099. R-ISO

|

M12x1.75

|

|

1.75

|

10

|

9.9

|

24.5

|

25.4

|

73

|

4

|

10.2

|

|

TMI/E. 14.200.4HI. 120116. R-ISO

|

M14x2.0

|

M17-M80x2.0

|

2.0

|

12

|

11.6

|

28.0

|

29.0

|

80

|

4

|

12.0

|

|

TMI/E. 16.200.4HI. 140136. R-ISO

|

M16x2.0

|

M17-M80x2.0

|

2.0

|

14

|

13.6

|

32.0

|

33.0

|

92

|

4

|

14.0

|

|

TMI/E. 18.250.4HI. 160148. R-ISO

|

M18x2.5

|

|

2.5

|

16

|

14.8

|

35.0

|

36.0

|

92

|

4

|

15.5

|

|

TMI/E. 20.250.4HI. 180171. R-ISO

|

M20x2.5

|

|

2.5

|

18

|

17.1

|

40.0

|

41.2

|

102

|

4

|

17.5

|

|

TMI/E. 24.300.4HI. 200199. R-ISO

|

M24x3.0

|

|

3.0

|

20

|

19.9

|

48.0

|

49.5

|

102

|

4

|

21.0

|

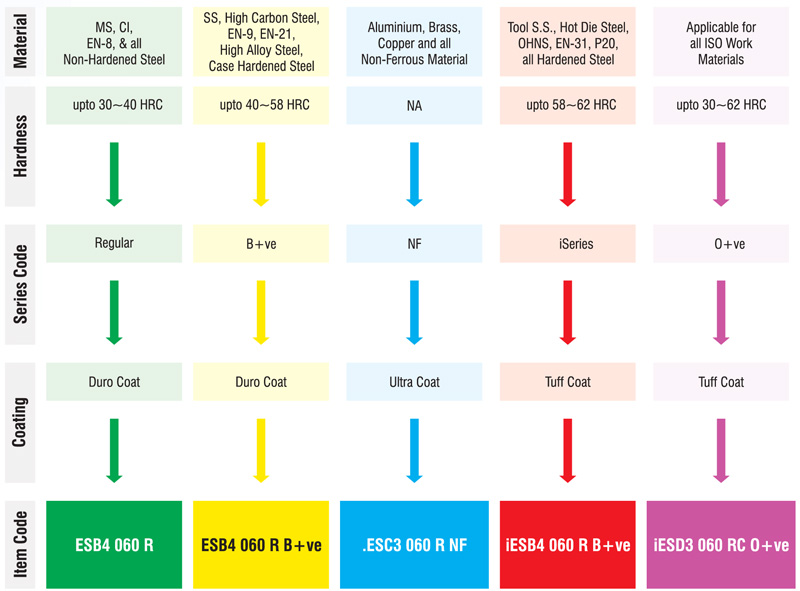

- For HRC>60, use Duro Coat

- For Through Coolant Threadmill, item Code will be TMI

- For Non-Through Coolant Threadmill, Item Code will be TME

- B+ve and i-Series available on request

|

MATERIAL GROUP

|

MATERIAL

|

MATERIAL

|

L

|

HARDNESS BENEFIT

HB |

CUTTING SPEED V/s

m/min |

Feed

f mm/tooth |

|

P

|

1

|

Unalloyed Steel

|

Low carbon (C=0.1-0.25)

|

125

|

50 – 200

|

0.025 – 0.3

|

|

P

|

2

|

Low alloy steel

(alloying elements≤5%) |

Non hardened

|

180

|

50 – 150

|

0.02 – 0.22

|

|

CHE / ISO50 / ER16-100

|

3

|

|

Hardened

|

275

|

40 – 150

|

0.01 – 0.15

|

|

M

|

4

|

Stainless Steel

|

Non hardened

|

200

|

50 – 120

|

0.01 – 0.13

|

|

CHE / ISO50 / ER 20-100

|

5

|

|

Austenitic

|

180

|

50 – 120

|

0.01 – 0.12

|

|

CHE / ISO50 / ER20-150

|

6

|

Stainless steel Cast ferritic

|

Hardened

|

330

|

50 – 90

|

0.01 – 0.1

|

|

K

|

7

|

Malleable

|

Ferritic (Short chips)

|

130

|

50 – 70

|

0.01 – 0.15

|

|

CHE / ISO50 / ER25-100

|

8

|

Grey cast iron

|

Low tensile strength

|

180

|

60 – 140

|

0.01 – 0.13

|

|

CHE / ISO50 / ER25-160

|

9

|

|

High tensile strength

|

260

|

35 – 100

|

0.01 – 012

|

|

CHE / ISO50 / ER 32-080

|

10

|

Nodular SG iron

|

Pearlitic

|

260

|

35 – 80

|

0.01 – 0.12

|

|

N

|

11

|

Aluminium alloys

|

Cast

|

75

|

80 – 160

|

0.03 – 0.36

|

|

CHE / ISO50 / ER32-160

|

12

|

|

Cast & aged

|

90

|

100 – 200

|

0.1 – 0.3

|

|

CHE / ISO50 / ER40-080

|

13

|

Copper and copper alloys

|

Brass

|

90

|

160 – 250

|

0.04 – 0.43

|

|

CHE / ISO50 / ER40-100

|

14

|

|

Bronze and non leaded copper

|

10

|

120 – 200

|

0.03 – 0.36

|

|

S

|

15

|

High temperature alloys

|

Annealed (Nickel or Cobalt based)

|

250

|

15 – 35

|

0.005 – 0.06

|

|

CHE / ISO50 / ER50-100

|

16

|

Titanium alloys

|

Pure 99.5 Ti

|

400 Rm

|

35 – 70

|

0.006 – 0.07

|

|

H

|

17

|

Extra hard steel

|

Hardened & tempered

|

45-50 HRc

|

15 – 45

|

0.004 – 0.04

|

|

CHE / ISO50 / ER50-100

|

18

|

|

|

51-55 HRc

|

15 – 30

|

0.004 – 0.04

|